Pallet wrapping is a crucial step in the transportation and storage of goods, ensuring their safety and stability throughout the journey. To achieve efficient and secure wrapping, the use of reliable pallet wrapping machines, such as the stretch wrapper or stretch wrap machine, is essential. These machines streamline the pallet wrapping process, saving time and effort while ensuring optimal results.

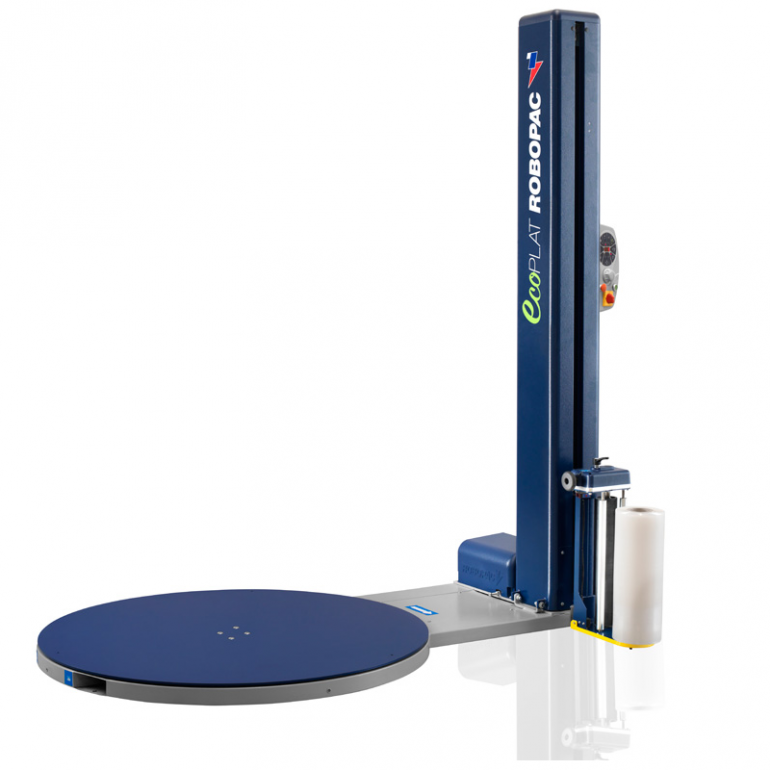

A pallet wrapper, also known as a stretch wrapper, is a specialized machine designed to wrap stretch film securely around a pallet and its contents. It helps create a tight and secure unit load, preventing shifting, toppling, and damages during handling and transit. With the ability to stretch film tightly around the pallet, a pallet wrapper provides enhanced load stability while minimizing material usage and costs.

Stretch wrapping machines work by rotating the pallet, while simultaneously applying the desired tension to the stretch film. This consistent and controlled wrapping process ensures that the film is evenly distributed, eliminating any weak spots that could compromise the integrity of the load. Additionally, some pallet wrappers offer advanced features such as automatic film cutting and attachment, making the operation even more efficient.

Investing in a pallet wrapping machine can bring numerous benefits to your business. By utilizing these machines, you can optimize your pallet wrapping process, increase productivity, and minimize the risk of product damage. Moreover, the use of stretch wrap machines enables you to save on film costs by ensuring efficient film usage, ultimately leading to cost savings in the long run.

Mastering the art of pallet wrapping techniques is essential for businesses involved in logistics, warehousing, and transportation. By understanding the capabilities of pallet wrappers and stretch wrap machines and implementing proper techniques, you can ensure your goods are securely wrapped and protected throughout their journey. So, let’s delve deeper into the world of pallet wrapping and explore the ultimate guide to mastering these essential techniques.

Choosing the Right Pallet Wrapping Machine

When it comes to pallet wrapping machines, selecting the right one for your needs is crucial. The market offers a variety of options, so it’s important to consider a few key factors before making your decision.

First and foremost, think about the size and weight of the pallets you will be wrapping. Different machines have varying weight capacity and maximum load dimensions. Ensure that the machine you choose can handle the specific requirements of your pallets.

Second, consider the level of automation you require. Some pallet wrapping machines are manual, requiring operator intervention to wrap the pallets, while others are semi-automatic or fully automatic. Automating the process can increase efficiency and save valuable time and labor costs.

Lastly, think about the stretch film you’ll be using. The type and thickness of the film can affect the performance of the pallet wrapping machine. Make sure the machine you select is compatible with the stretch film you plan to use, as this will ensure optimal wrapping results.

By taking these factors into account, you can confidently choose the right pallet wrapping machine for your business, improving efficiency and ensuring secure and stable pallet loads.

Mastering the Stretch Wrap Technique

In order to become proficient in the art of pallet wrapping, mastering the stretch wrap technique is essential. This technique ensures that your pallets are securely wrapped and protected during transport or storage. With the right knowledge and skills, you can achieve optimal results and minimize the risk of any damage occurring to your valuable goods.

To begin, it is crucial to select the appropriate stretch wrap machine for your specific needs. There are various types of machines available, including semi-automatic and fully automatic options. Consider the size and weight of your pallets, as well as the desired level of automation, when making your choice. Investing in a high-quality stretch wrap machine will greatly contribute to the effectiveness of your wrapping technique.

Next, it’s important to properly prepare your pallets before applying the stretch wrap. Make sure that your goods are evenly distributed and stacked securely on the pallet. This will help prevent shifting during the wrapping process, ensuring stability and reducing the risk of damage. Take the time to organize and arrange your items in a way that maximizes their stability.

When wrapping the pallet, start by anchoring the stretch wrap to the pallet itself. This can be done by either using a hand wrap technique or by utilizing the features of your stretch wrap machine. Begin at the bottom of the pallet and work your way up, focusing on tightly securing the wrap around the base of the goods. As you move upward, overlap each layer of wrap slightly to create a secure and uniform coverage. Continue wrapping until you reach the top of the pallet, ensuring all sides are adequately covered.

By mastering the stretch wrap technique, you will enhance the efficiency and effectiveness of your pallet wrapping process. Remember to choose the right stretch wrap machine, properly prepare your pallets, and use a systematic approach when wrapping. These key factors will contribute to the safe transportation and storage of your goods, ultimately providing peace of mind and ensuring customer satisfaction.

Shrink Wrapper

Troubleshooting Common Pallet Wrapping Issues

Pallet Film Breakage

One common issue that can occur during pallet wrapping is film breakage. This problem can arise due to various reasons, such as using low-quality stretch wrap or applying excessive tension while wrapping. To prevent film breakage, ensure that you are using high-quality stretch wrap that is appropriate for your pallet load. Additionally, make sure to adjust the tension settings on the pallet wrapper to provide just enough pressure for a secure wrap without putting too much stress on the film.

Uneven Film Distribution

Uneven film distribution can lead to weak spots on the pallet load, making it susceptible to damage during transport or storage. To address this issue, pay close attention to how the film is being applied during the wrapping process. Make sure that the film is evenly distributed across the entire pallet load, with no loose or sagging sections. Adjust the tension and speed settings on the stretch wrap machine if necessary to achieve a uniform and tight wrap.

Pallet Load Instability

If your pallet load is not stable after wrapping, it can result in shifting, tipping, or damage to the goods during handling. To troubleshoot this issue, first, ensure that you are using the appropriate amount of stretch wrap layers for the weight and size of your pallet load. If the load is still unstable, consider using additional techniques such as corner board protectors or edge reinforcements to further secure the load. Additionally, double-check the settings on the pallet wrapper to ensure that the correct amount of tension and containment force is being applied during the wrapping process.